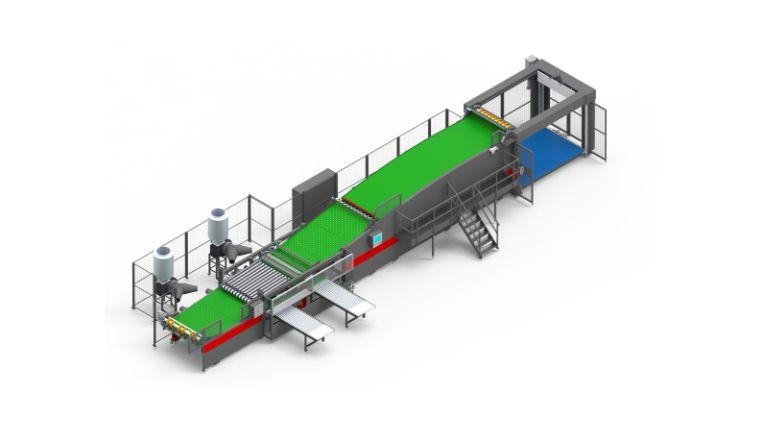

FULL STACKER - FullStack

Full Stacker for Digital Printing Single Pass

Overview

Stacker for stacks and sheets up to 2m for digital printing lines

Digital printing lines for corrugated board require reliable and versatile machines to ensure efficient and high-quality production. SERRA's FullStack is a robustly designed machine that offers exceptional reliability, work versatility, and an automatic rejection table. This machine is capable of stacking sheets and stacks of up to 2 m in length, making it ideal for high-volume production lines.

SERRA's FullStack with automatic rejection is a reliable and versatile machine for digital printing lines for corrugated board. The machine offers exceptional reliability, work versatility, and an automatic rejection table, increasing efficiency and productivity in production lines. Its capability to handle sheets and stacks of up to 2 m in length, and robust and long-lasting design, make it a valuable investment for businesses in the digital printing industry.

Exceptional reliability

- SERRA's Full Stacker is designed to achieve work-flow continuity with shingling transport, ensuring exceptional reliability in high-volume production lines.

- The anti-jam technology used in its construction prevents any potential jams, making it a reliable investment for businesses.

- High-quality materials are used in its construction, providing exceptional stability and durability.

Robust and long-lasting

- The Full Stacker is a robust and long-lasting machine that can handle stacks and sheets of up to 2m in length.

- It is versatile and ideal for handling various sizes and thicknesses of corrugated board, providing flexibility in production lines.

- The machine comes equipped with an automatic rejection table that allows for easy sampling and rejection plate accumulation, increasing efficiency in production.

Automatic rejection table

- The Full Stacker's automatic rejection table allows for easy rejection plate accumulation, reducing downtime in production lines.

- It also allows for easy sampling, providing quality control for businesses.

- The rejection table is an essential feature for businesses that require consistent and reliable quality control in their production lines.

Robust and long-lasting

- The Full Stacker is a robustly designed machine that is responsive and reliable.

- The machine's anti-jam technology and high-quality materials provide exceptional stability and durability, making it a long-lasting investment for businesses.

- It can handle high-volume production lines without any interruptions or delays, providing businesses with a reliable and efficient solution.

Features

Adjustable stack height:

The Full Stacker can be adjusted to handle different stack heights, allowing for customization based on specific production needs.

Customizable stacking patterns:

The machine can be programmed to create different stacking patterns, providing flexibility in production and allowing for customization based on customer requirements.

Precision stacking:

The Full Stacker's precision stacking technology ensures that each stack is perfectly aligned and tightly packed, preventing damage to the printed materials.

Automated stacking process:

The machine's automated stacking process reduces the need for manual labor, increasing efficiency and productivity in production lines.

Smooth sheet handling:

The machine's smooth sheet handling technology ensures that each sheet is handled gently and without damage, maintaining the integrity of the printed materials.

User-friendly interface:

The Full Stacker's user-friendly interface allows for easy operation and monitoring of the stacking process, reducing the risk of errors and increasing efficiency.

Easy maintenance:

The Full Stacker is designed for easy maintenance, with quick and easy access to critical components for repairs and cleaning.