QUICK DIE CHANGE - SerrApid

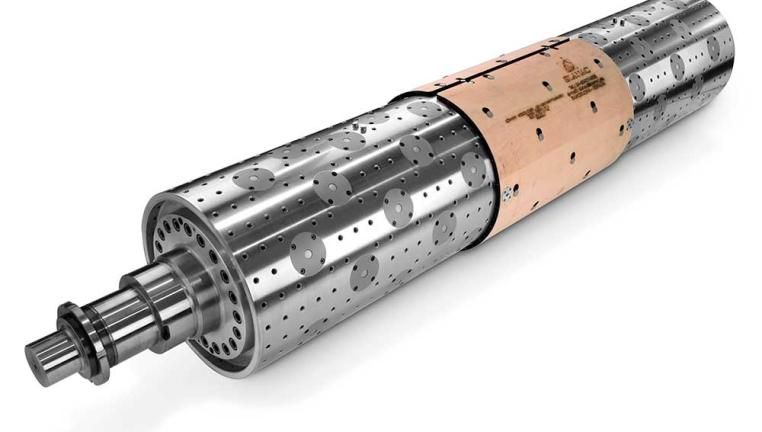

Quick rotary die change cylinder

Overview

SERRAPID® is a highly advanced quick-change rotary die cutting cylinder that is designed to enhance the productivity and quality of die cutting machines. It is a world-leading technology that is based on extensive knowledge and experience, offering a remarkable level of automation and operator-friendly features. With SERRAPID®, die changes can be performed in less than 30 seconds, leading to increased productivity, reduced downtime, and improved profitability.

SERRA's SERRAPID® is the most advanced quick-change rotary die cutting cylinder on the market, offering amazing set-up times, high-speed performance, durable technology, and cost-saving benefits. It is an operator-friendly and versatile solution that ensures safe and simple die changes and reliable operation, leading to improved productivity, quality, and profitability. With SERRAPID®, die changes can be performed in less than 30 seconds, leading to increased productivity, reduced downtime, and improved profitability.

Amazing set-up time

- Speeds up rotary die mounting to 30 seconds per shell, reducing downtime

- Ensures safe and simple die changes, increasing productivity

- Remarkable level of automation

- Operator-friendly, efficient, and versatile, leading to improved quality and faster production times

High-speed performance

- Offers a remarkable level of automation, leading to faster and more efficient production times

- Ensures high productivity, leading to increased profitability

- Provides excellent die-cutting quality, leading to improved customer satisfaction

Durable technology

- Based on world-leading technology, ensuring a reliable and long-lasting solution

- Requires low maintenance, reducing costs and increasing uptime

- Ensures great product quality, leading to improved customer satisfaction

Saving time and money

- Extends the life of your dies and anvil covers, reducing costs

- Offers an excellent price/performance ratio, leading to improved profitability

- Easy to maintain, reducing maintenance costs and improving uptime

Features

Protect Your Investments

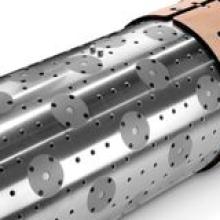

SERRAPID® is Installable on all rotary die cutters on the market and can even make dies of different RDC brands interchangeable. All bolts have “bolt protector” inside to avoid ware out and to ease its maintenance

Safety

Technicians can mount dies quickly without worrying about missing or improperly torqued bolts like on conventional die-mount systems. In case of air loss during operation, the die will be lock on the cylinder surface by the pins. Special auto-locked handles to avoid cuts during handling

Air inlet

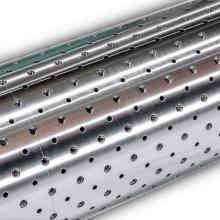

At the press of a switch, compressed air is injected into the cylinder, forcing the mushroom hold-downs outward with a force of 1300 N of force (290 lbs.

Team Fast Training

Onsite safety and product training at the time of installation prepares your team to work with SERRAPID® efficiently from day one. The cylinder is protected by several world patents and optimized thanks to the continuous improvement process that Serra carries out to guarantee the best product quality.

Updates

SERRAPID® is protected by several world patents and optimized thanks to the continuous improvement process that Serra carries out to guarantee the best product quality.

No tools required

No additional hardware or special hand tools are required to secure the die to the cylinder, ensuring fail-safe operation.

Operation

The prepared die shell is fit onto the cylinder with the mushrooms protruding through keyhole openings. The shell is slid into position, the compressed air is released, and the hold-downs retract, clamping the shell in place with approximately 1300 N of force (290 lbs of force).

Suitable for any existing machinen

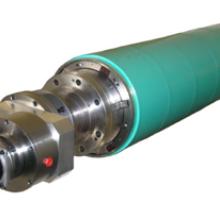

Installable on all rotary die cutters, and allows to interchange dies between machines from different OEM’s. It reproduces the same bolt pattern as the original die cutting drum

Smooth cutting surface

Eliminates the need for anvil grinding and also increases the lifespan of your anvil covers and dies.

Specifications

Processed materials

Corrugated board: 1.4 to 10 mm

Corrugated flute type: F, E, B, A, C, EF, EB, BC, AB, AC

Capability

Sheet size width: 1600 to 2490 mm

Speed: 11000 b/h

Sheet sizes

Sheet length "L": 450 to 1540 mm

Dimensions & weight

Length (2): 9.8 m

Width (2): 9.8 m

Diameter: 40 mm

Net weight: 48 t

Force

Down pin force: 1300 N of force (290 lbs of force)

Lateral pin resistance: 1300 N of force (290 lbs of force)

Stopper resistance: 1300 N of force (290 lbs of force)

Needed

Compressed air: 120 psi (8.3 bar)

Energy consumption: 300 kWh

In action

SERRAPID INSTRUCTIONS

Step by step instructions how to work with Serrapid, the quick mount die system

SERRAPID: Rotary Die Cylinder

Green Bay Packaging – Cincinnati, Ohio

Prior to upgrading to the SERRAPID® system, GBP spent up to 20 minutes changing dies on their traditional bolt-on cylinder. With their new SERRAPID® cylinder, GBP is mounting dies in about 1 minute and 10 seconds and setting up for the next run in 3-4 minutes.

Green Bay Packaging – Cincinnati, Ohio

Prior to upgrading to the SERRAPID® system, GBP spent up to 20 minutes changing dies on their traditional bolt-on cylinder. With their new SERRAPID® cylinder, GBP is mounting dies in about 1 minute and 10 seconds and setting up for the next run in 3-4 minutes.